Storage tanks are used across industries to store and protect process liquids and materials of many kinds such as chemicals, oil, gas, water, wastewater, raw materials, and more. There are many types of storage tanks available on the market of varying sizes, shapes, purposes, accessories, and materials, and most can be customized to meet specific application needs.

Using our in-house unique extrusion winding capabilities, Houston PolyTank custom fabricates industrial-strength plastic storage tanks up to 50,000 gallons.

What are Industrial Storage Tanks?

Industrial storage tanks see broad uses for short- and long-term material storage in a variety of industries. Here are some examples:

- The chemical industry uses plastic storage tanks for material storage, and as reactors for various chemical processes.

- Renewable power generation operations use large, extrusion-wound polyethylene and polypropylene tanks as battery casings for large chemical batteries used to store energy in a chemical form collected from renewable sources.

- Water and wastewater facilities use plastic tanks for processing and water treatment operations.

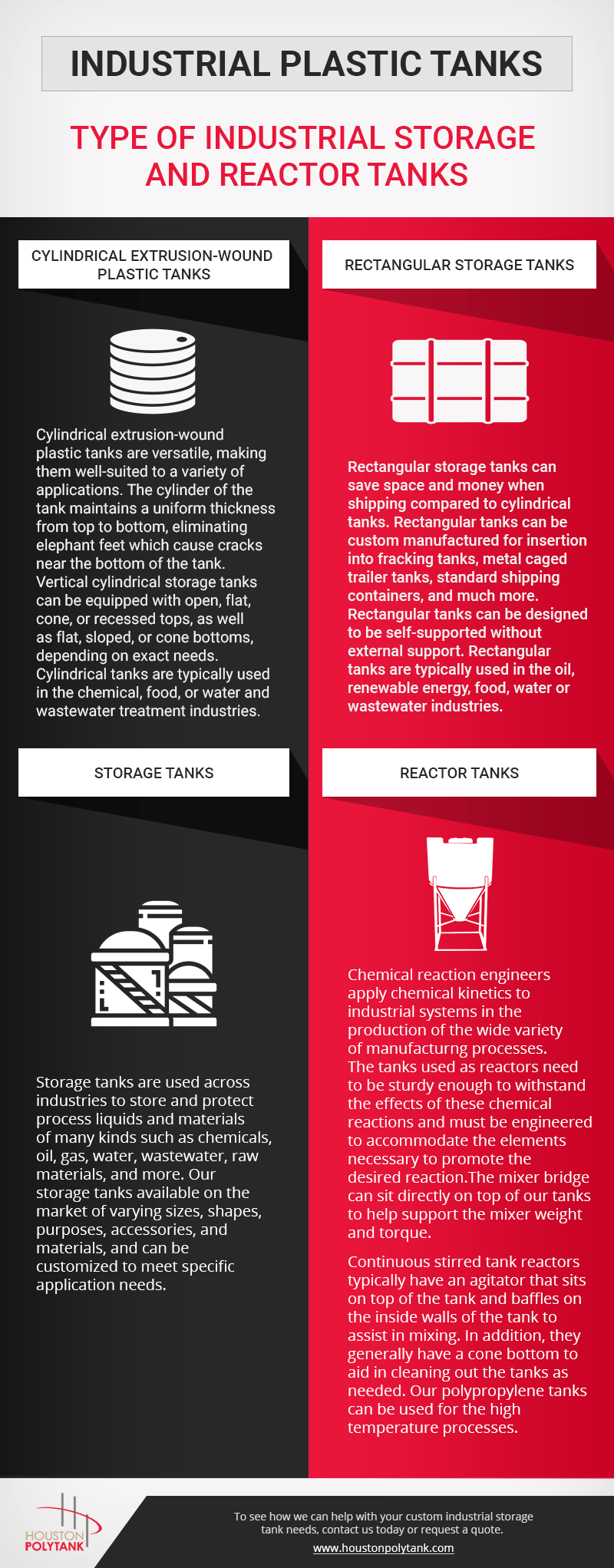

There are many types of industrial storage tanks that vary in terms of shape, intended use, and material composition. The most common shapes include cylindrical and rectangular tanks. There are other features that can be customized, such as:

- The bottom of most tanks may be flat or cone-shaped.

- Tops can be open or closed.

- Rectangular tanks can be made in a variety of dimensions.

- Cylindrical tanks may be horizontal or vertical.

Type of Industrial Storage Tanks

Houston PolyTank offers various industrial storage tanks. Cylindrical and rectangular industrial storage tanks each offer their own advantages. Our industrial storage tanks are made of high-density linear polyethylene or polypropylene and are heat-resistant up to 120 °F and 200 °F, respectively. We use plastics that are corrosion- and chemical-resistant to both acidic and alkaline compounds (pH 0-14) and feature low moisture adsorption, making them ideal for safely maintaining the integrity of chemical process materials.

Our tanks are produced with high tensile and compressive strength, leading to a longer service life and lower maintenance costs compared to alternative materials such as steel or fiberglass. Houston PolyTank has molds to manufacture plastic tanks ranging from 50–50,000 gallons. We also provide an extensive portfolio of attachments and accessories for your tanks, such as ladders, handrails, mixer mounts, immersion heaters, liquid level indicators, side manway options, and more.

- Cylindrical extrusion-wound plastic tanks are versatile, making them well-suited to a variety of applications. The cylinder of the tank maintains a uniform thickness from top to bottom, eliminating elephant feet which cause cracks near the bottom of the tank. Vertical cylindrical storage tanks can be equipped with open, flat, cone, or recessed tops, as well as flat, sloped, or cone bottoms, depending on exact needs. Cylindrical tanks are typically used in the chemical, electrical, or water treatment industries.

- Rectangular storage tanks can save space and money when shipping compared to cylindrical tanks. Rectangular tanks can be custom manufactured for insertion into fracking tanks, metal caged trailer tanks, standard shipping containers, and much more.

Industrial storage tanks have many uses in various industries. Houston PolyTank offers both cylindrical and rectangular extrusion-wound tanks made from high-density polyethylene or high-density polypropylene, offering many advantages over other tank materials. To see how we can help with your custom industrial storage tank needs, contact us today or request a quote.