The GOAL in proper installation is to avoid continuous weight, vibration and any expansion or contraction restriction to the plastic tank/fittings. The SOLUTION is expansion joints and spring supports.

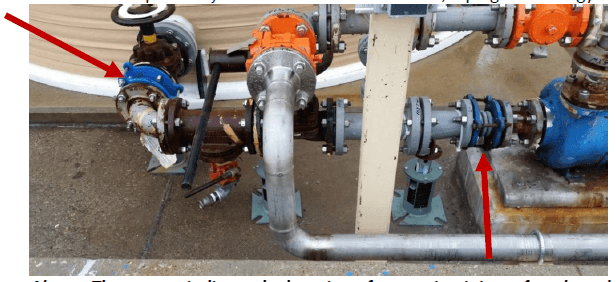

Expansion Joints

Plastic tanks are influenced by thermal expansion and contraction due to changes in the temperature. The coefficient of expansion in plastic is greater than metal by 19 times. One should avoid restrictions due to hard plumbing. Using expansion joints will allow the tank to expand and contract without causing abnormal forces on the plastic.

Expansion joints also isolate the tank and its fittings from vibrations from pumps, valves, etc.

Vendors for expansion joints include Proco Products, Piping Technology and Products, etc.

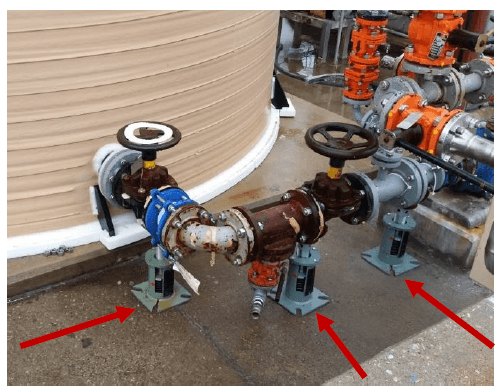

Spring Supports

Heavy valves, pumps, heaters and plumbing can cause excess weight on the tanks/fittings. In general, plastic can crack when continuous extensive force is on it.

The spring supports are placed under the valves, pumps, etc. to support the load to the ground to avoid continuous weight on fittings. The resistance of the springs allow vertical movement during thermal expansion and contraction.

The spring supports need to be designed to carry the load of valves, pumps, etc. during expansion and contraction.

Vendors for expansion joints include Piping Technology and Products, Anvil International, etc.